- Home

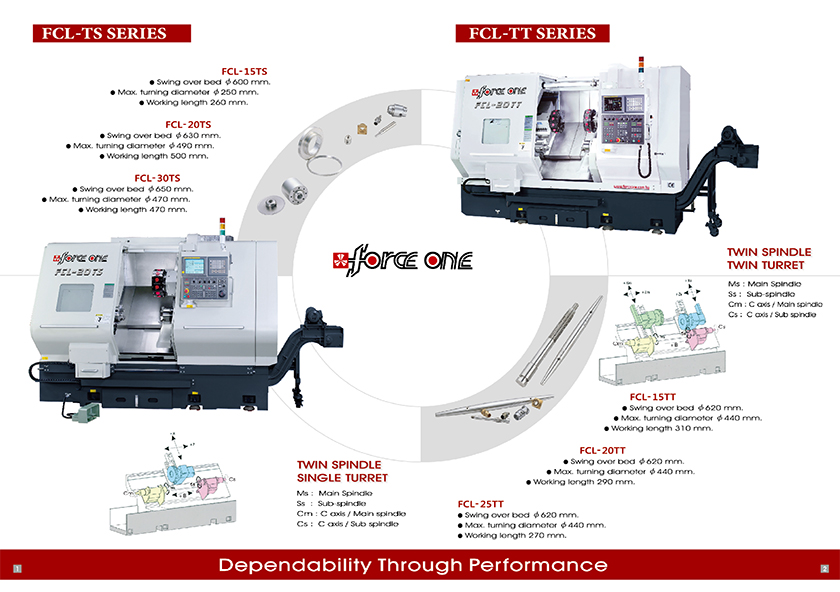

- Turn Mill center / Twin spindle, Single turret

- FCL - 20 TS / Turn Mill center / Twin spindle, Single turret

FCL - 20 TS / Turn Mill center / Twin spindle, Single turret

RUGGEDLY AND PRECISELY CONSTRUCTED THROUGHOUT (linear guide way)

STANDARD ACCESSORIES OPTIONAL ACCESSORIES

SPECIFICATION

| Swing over bed | Ø 630 mm ( 24.8” ) |

|---|---|

| Max turning diameter | Ø 490 mm ( 19.29” ) |

| Working length | 500 mm ( 16.68” ) |

| Spindle nose | Main : A2 - 6 Sub : A2 - 5 |

| Bar capacity | Ø 51 mm ( 2” ) Ø 45 mm ( 1.7” ) |

| Hydraulic chuck | Ø 210 mm ( 8” ) Ø 169 mm ( 6” ) |

| X axis travel | 280 mm ( 11.02” ) |

| Z axis travel | 560 mm ( 22.05” ) |

| B axis travel | 500 mm ( 19.68” ) |

Features

- The overall structure is made using Meehanite cast iron and is annealed to eliminate internal stress, providing high rigidity and stability.

- It features a 12-position turret with a bi-directional random tool selection method, where tool positioning takes only 0.6 seconds. The turret can hold 20x20 mm external diameter tools and 32 mm internal diameter tools.

- Both the main and sub spindles are synchronously operated, allowing for one-time completion of workpieces.

- The main spindle is designed as a barrel-type structure, utilizing P4 bearings for high axial thrust, radial stability, and precision, thus supporting larger lathe cutting operations.

FORCE ONE MACHINERY

FORCE ONE Machinery has over 20 years experience, and the company’s Chief Engineer of CNC has 20 years background.

E - catalogs